RED SEAL ELECTRIC IS YOUR

Calcium Silicate Board Supplier and Fabricator

Calcium Silicate Properties

Calcium silicate board is a versatile insulation material widely used in various industrial applications due to its high-temperature structural integrity, high compressive strength, and corrosion inhibition properties. It effectively insulates high-temperature pipes and equipment, making it ideal for fire endurance applications and addressing common concerns about insulation integrity.

Composed of inorganic, non-combustible, non-asbestos materials, calcium silicate insulation is made by pulping and molding mineral fibers or cellulose fibers, which are then cured under high temperatures to form durable boards. This robust composition ensures reliable performance in demanding industrial environments.

View Our Stock Calcium SIlicate Board

Industries Using our Calcium Silicate Materials

-

Power Generation

-

Oil & Gas

-

Construction

-

Marine Transport

-

Industrial Kilns

-

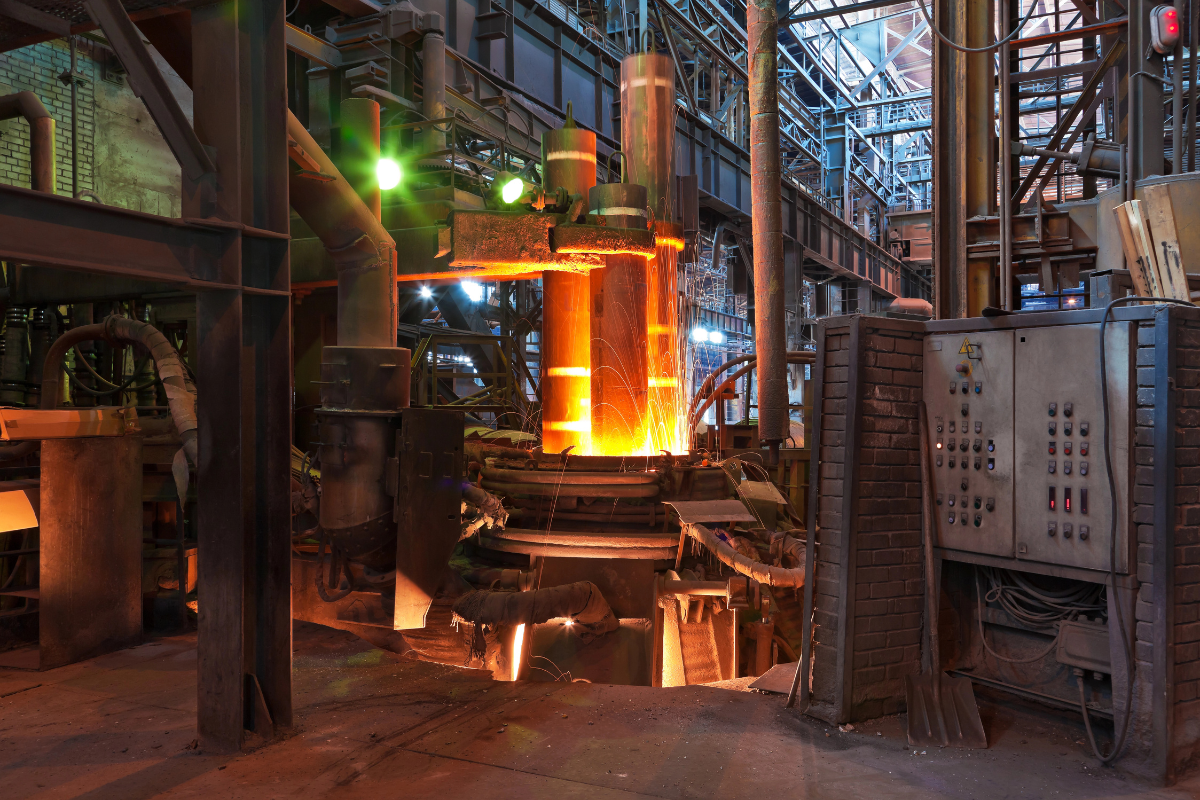

Steel & Metal Foundry

Your trusted partner for Calcium Silicate Board Distribution and fabrication

we’ve got it all ready to go…

…including calcium silicate board, such as:

Frequently Asked Questions

-

Calcium silicate board is widely used in various industrial applications due to its excellent properties. It serves as an effective insulation material with high-temperature structural integrity, high compressive strength, and corrosion resistance. These boards are commonly utilized to insulate high-temperature pipes and equipment, ensuring efficient thermal management and safety. Additionally, they are essential for fire endurance applications, providing reliable fireproofing solutions. Their robust construction quells common concerns about insulation integrity, making them indispensable in industries such as power generation, petrochemical, and manufacturing.

-

Calcium silicate board is composed of inorganic, non-combustible, non-asbestos materials, making it a safe and reliable insulation option. The manufacturing process involves pulping mineral fibers or cellulose fibers, which are then molded and subjected to high temperatures to cure and harden. This process transforms the materials into durable calcium silicate boards, known for their exceptional structural integrity and ability to withstand high temperatures. These characteristics make calcium silicate boards an ideal choice for a wide range of industrial applications.

-

If you’re interested in purchasing calcium silicate board or looking for fabrication, contact the Red Seal team by filling out our quote form.

An inorganic, incombustible material composed primarily of lime, silica and reinforcing fibers. The material is 40 pcf (641 kg per m3) and rated to 1,700°F.